TEBO Software

Uniquely in the electronics industry for fast testability analysis. A cost effective solution to help reduces time and minimize errors in developing your test programs and test fixtures.

Call Us: +65-67107997

Design for Testability

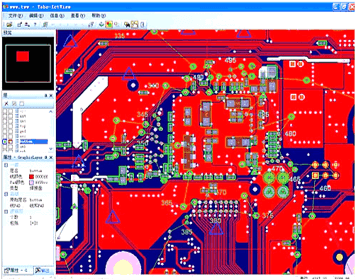

Design for testability software, TEBO TA V6.0 (DFT) , can quickly and accurately translates your import CAD or Gerber into real reference designators, netlists, X/Y component pin geometries, component height and size, values, tolerances, part numbers, etc. with the material BOM data through intelligent integration testing process and fixture manufacturing requirements.

It creates a detailed understanding of the PCB circuit network, parts test coverage, test probes layout and distribution information by generating DFT analysis reports down to a few minutes of work. A software tool not only shorten the time of new product introduction (NPI) and reduces the cost of test fixture.

- Testability Analysis Reports

Generate Jig analysis / Network testing / Parts coverage / Probe size and distribution information report / Categorise reasons for no probe insertion. - Gerber/CAD Version Compare & BOM Check function

Compare different version of Gerber & CAD data source to identify components differences. - Output element (BGA/IC) probe report. It report the probe type/quantity/force status to avoid excessive distribution of test points on the PCB board that may cause high tension force at the bottom of IC Chip to over strain.

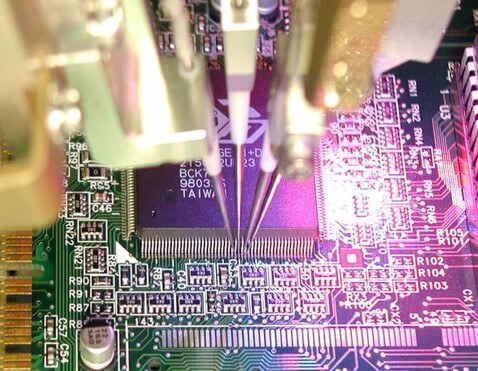

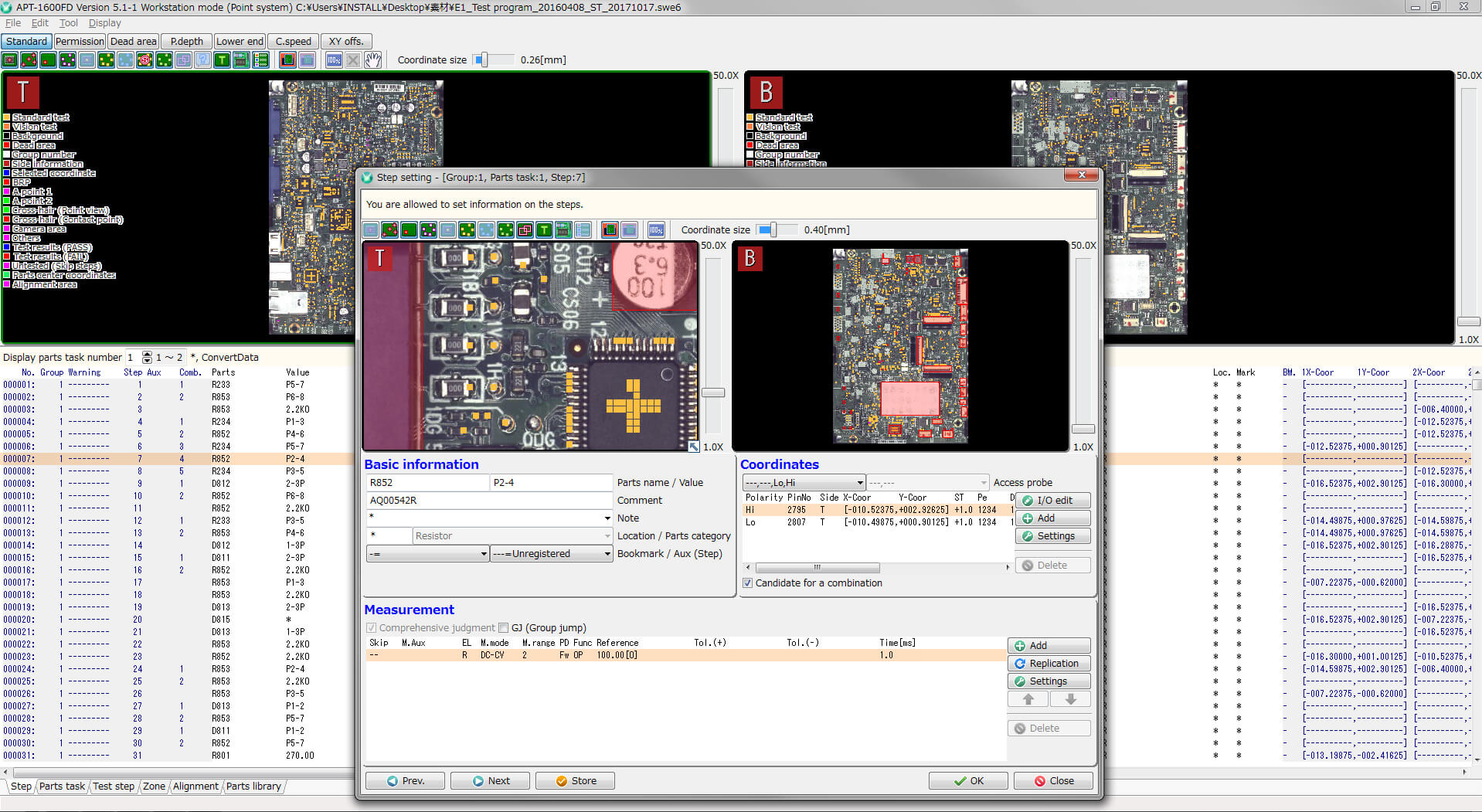

Flying Probe Application

Software automatically identifies PCB buried blind holes and non-accessible components to ensure the contact locations and parts that are close to tall devices will not be tested.

BGA/CSP devices test points will be selected automatically and deployed to the best location on the network. Open/Short test will be intelligent optimization based on the surrounding components footprint. This ensure full coverage on BGA/CSP parts and reduces test time.

Software automatically offset components test pads contact position on tilted or angled SMD components. The test points can be displayed in the simulated software without the need to perform manual checks using flying probe tester.

No-fly Zone domain (output to the program) can be automatically extracted from the CAD component height data (Library). The function is supported using PCBA 3D ( IGES/IDF ) output which helps to save time improve equipment utilization.

Products

Flying Probe Test

3D Metrology Test

ICT Test Fixture

Stencil Cleaners & Detergent

Design for Testability

Robotic Test Handling

Get In Touch

Interested in our products and services? Drop us your inquiry here.

MEET SYSTEST

GOOGLE MAP