ICT Fixture Manufacturers

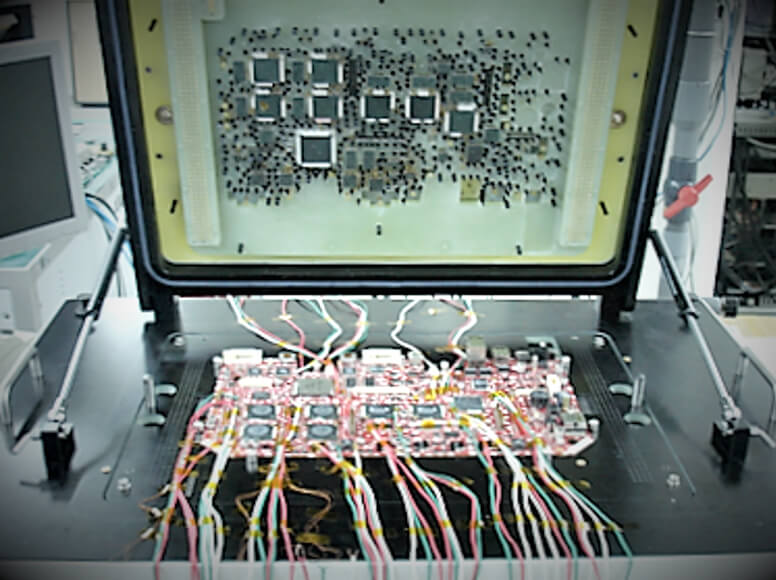

SYSTEST, one of the leading ICT fixture manufacturers in Singapore, supports the two most popular choice of In-Circuit Test (ICT) test systems use by global EMS & OEM for testing of printed circuit board assemblies. We offers full turn-key solutions from test program development to fabrication of Teradyne & Keysight test fixtures.

Call Us: +65-67107997

Established since Y2008 under the brand of LDX Technologies, our continuous strive in quality excellency is a long term commitment towards our valued customers who trusted in the products that we delivered.

Our manufacturing workflow is tracked real-time which is built on a web-based enterprise management system by integrating our inventory control / design-to-testability / machining time / wiring schedule / final assembly / acceptance testing & QC certification for shipment. The software enables an extensive traceability on every projects assigned should an inquiry is needed on field return issue.

Our clients include international OEM and EMS with strong presence in Asia.

Our Capabilities

In-circuit testing provides electronic manufacturers the highest fault coverage verification method for the SMT assembly process. SYSTEST ICT fixtures are robust, reliable and designed to cover a large range of PCB sizes with no compromise of quality in mind. We stock a wide range of fixture sizes and offers various actuation methods to meet your test demands.

Fixture Options

- Dual-stage vacuum

- Bi-level pneumatic cylinder

- Inline & automatic clamp

- Zero-flex guided probe

- Mechanical access to Connector Pins

- Auto barcode identification

- Automatic board marker

- BGA Safe – Protect module

Finite Element Analysis (FEA)

- Board Stress Analysis Simulation

- Strain Gage Measurement

Test Coverage

-

Open device pins

-

Analog component value and tolerance

-

Digital component functionality

-

LED color check

-

UUT power-up test

-

Frequency measurement

-

Boundary scan and Built-in Self Test

-

PLD programming

-

Virtual Pin & Cluster Tests

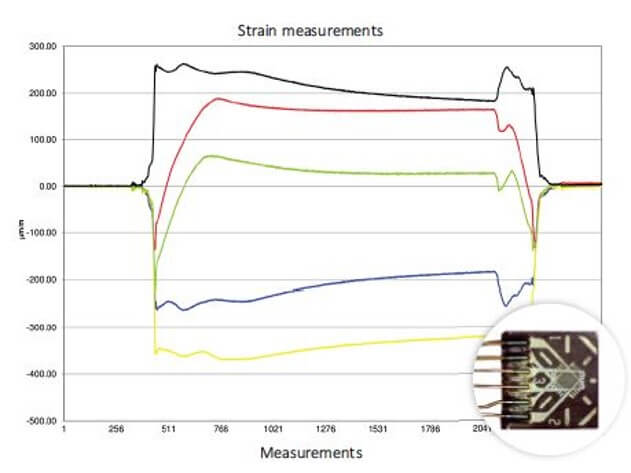

Board Stress Analysis

Board stress has becomes a major concern for most PCBA manufacturer. A larger surface mount component such as BGA, highly populated PCBs and brittle solders, board stress can be predicted using sophisticated software tools, and real-time strain measurements can be achieved using strain gauges. At SYSTEST, we have developed the skill set on both techniques to better prevent PCB damage under test.

- Software analysis is conducted during the fixture design stage using our unique Finite Element Simulation tool. The software tool allows the simulate forces involved on a UUT to identify any potential hot spot areas under stress that cause by PCB warpage or stiffening effect of components.

- Strain gages are installed on your UUT, and measure PCB strains during the buy-off process. A full detailed report is provided during fixture shipment.

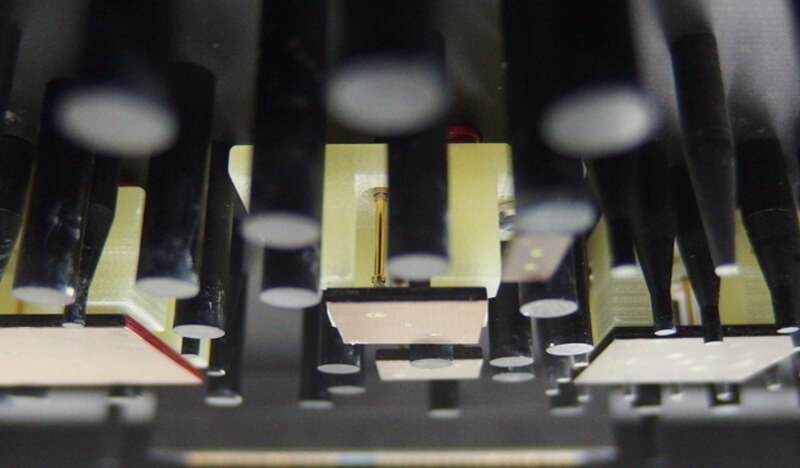

BGA Safe – Protect Module

SYSTEST custom design to provide special support for BGA device against risk of damage due to large contact points beneath the board.

Features :

Integrated with sensor plate for Open/Short pin test

Springs loaded module to adapt BGA package height and variation

Reduces board warpage for high probe count under BGA

Reduces stress on BGA to prevent balls crack

Types of Fixture Actuation Methods

Vacuum

Pneumatic

A premium quality fixture that demands precision contacts in a controlled actuation for a high complex PCB board sensitive to physical board stress when vacuum is undesirable. The fixture mechanism is specially design to overcome external environmental factors inside the test chamber that may cause damage to the board during test. It is very important to ensure board under test is safe and protected.

Automated Inline

Fully automatic fixture use for mass volume production in a inline board handler or with collaborative robot (Cobot), or a compact size industrial robot for speed and accurate performance. It reduces the reliance of operator to minimize human error which could result in undetected board damaged when mishandled.

Products

Flying Probe Test

3D Metrology Test

ICT Test Fixture

Stencil Cleaners & Detergent

Design for Testability

Robotic Test Handling

Get In Touch

Interested in our products and services? Drop us your inquiry here.

MEET SYSTEST

GOOGLE MAP