Amfax a3Di

Consistently Accurate & Robust Measurements

A patented dual laser technology to provide consistently accurate, non-contact measurements in the manufacturing environment.

Call Us: +65-67107997

Automatic 3D Inspection (a3Di) Metrology Test System

The fully automated Qualty Inspection System manufactured by Amfax is an Automated 3D Inspection(a3Di) metrology system that uses a laser-based absolute measurement technology to profile components and solder joints in true 3D.

These measurements are then validated against 3D CAD models to ensure that they are accurate and robust. The system is unaffected by component types, PCB color, lighting, height, position or board warpage ensuring accurate and repeatable measurement inspection results with near zero false calls.

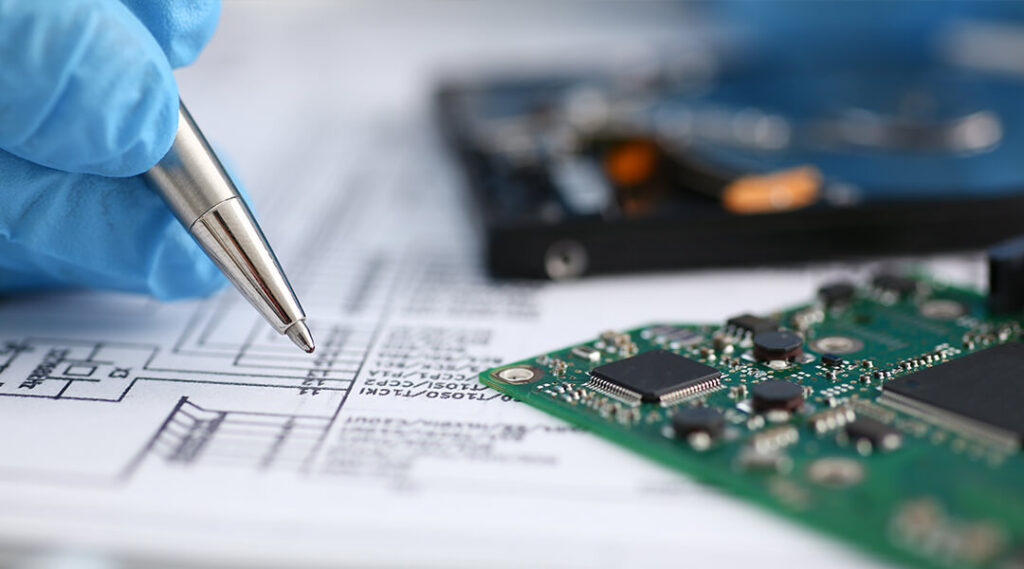

Metrology precision in PCBA inspection can help you eliminate process defects; defects you might not know are there. While the a3Di finds more true defects, its precision and measurement based programming limit false calls and the need for human intervention.

Programs are generated from CAD, debugged and typically stable within 1-2 hours. The results generated are x,y,z measurements with limits that conform to IPC 610 class 1,2 and 3 standards. These results can feed directly into industry standard SPC systems, providing real-time data to control and improve your manufacturing process.

System Benefits

A fully inline automated Metrology Inspection System – the Amfax a3Di is a revolutionary technology which provides accurate, repeatable non-contact based inspection measurements for printed circuit boards and other electronic parts in both electronic and mechanical manufacturing processes.

- Super-fast true 3D operation

- Detects faults more accurately & reliably than traditional AOI systems

- Near zero false call rate

- Conforms to IPC SMEMA standard for all conveyor systems

- Simple and fast to program and stabilize programs

- Adjustable resolution down to 1um

- Absolute x,y,z measurement system with SPC output

- Inspects component sizes <01005

- IPC 610 level 1, 2 and 3 compliant

- Modular design for easy maintenance

System Features

- Very high speed inspection rates – 7,200 mm2 /sec.

- Profile storage – complete 3D scans can be stored for future retest against improved and modified test limits without the need to re-scan.

- Absolute measurement system which means a real 3D mechanical inspection of components and solder joints.

- The results output is x, y and z measurements making true SPC possible, providing a new tool for refinement of the manufacturing process.

- The a3Di is the only PCB inspection machine on the market able to measure and qualify inspection to IPC 610. Position on the factory floor – Pre-reflow, Post-reflow, end of line, solder paste inspection, goods in inspection, mechanical inspection, off line metrology and rework inspection

The result – a3Di delivers a near zero false call rate and is quick to program and stabilize by taking your printed circuit board assembly operations to the next quality level !

- <01005 packages

- tombstone

- missing or excess solder

- solder bridges

- polarity

- rotation

- BGA reflow drop and co-planarity

- through-hole Pins

- crocodile

- bill-boarded

- shift, registration

- IPC 610 1, 2 and 3 compliance

- bridging

- 3D solder profile

- solder volume

- connectors (missing, damaged, bent pin, co-planarity)

- mechanical objects

- laser etch (MCR)

- silk screen (MCR)

- device co-planarity

- board warp measurement

- board stretch measurement

- wire-mod

- foreign object detection

- lifted or missing lead

- extra component

Products

Flying Probe Test

3D Metrology Test

ICT Test Fixture

Stencil Cleaners & Detergent

Design for Testability

Robotic Test Handling

Get In Touch

Interested in our products and services? Drop us your inquiry here.

MEET SYSTEST

GOOGLE MAP